Hello all,

Quick note over here from the world of failing AirCAM’s. I recently had a 2nd failure of my exterior mounted AirCAM. Since the RMA process was coming up bunk I decided to attempt a repair myself. I run an electronics engineering lab so have access to equipment (hot-air reflow, metcals, etc.)

The camera under repair is one I had die in operation about about 3mo of continuous use. The camera was exhibiting a condition where it would link up (sometimes at 100BaseT, always at 10BaseT) but I could never reach the GUI or do anything but SOMETIMES ping the unit (192.168.1.20). Flexing the PCB or agitating the camera didn’t seem to make a difference.

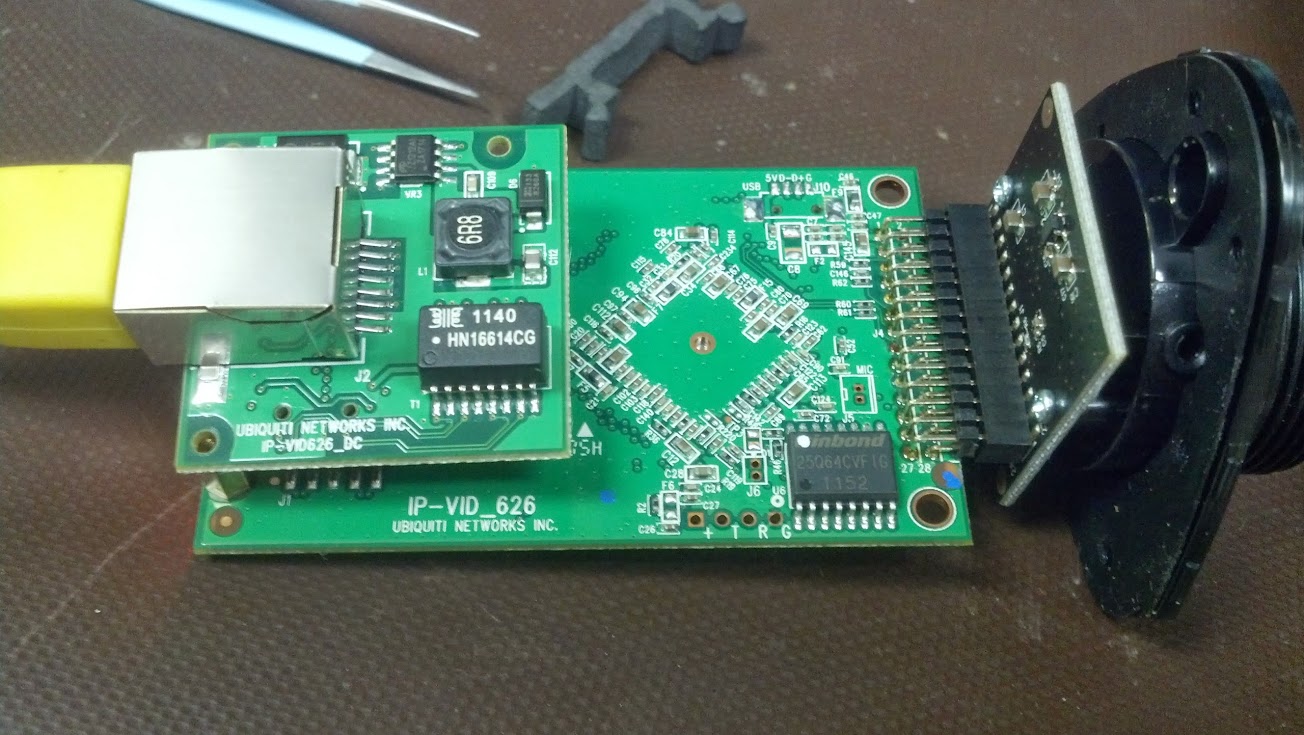

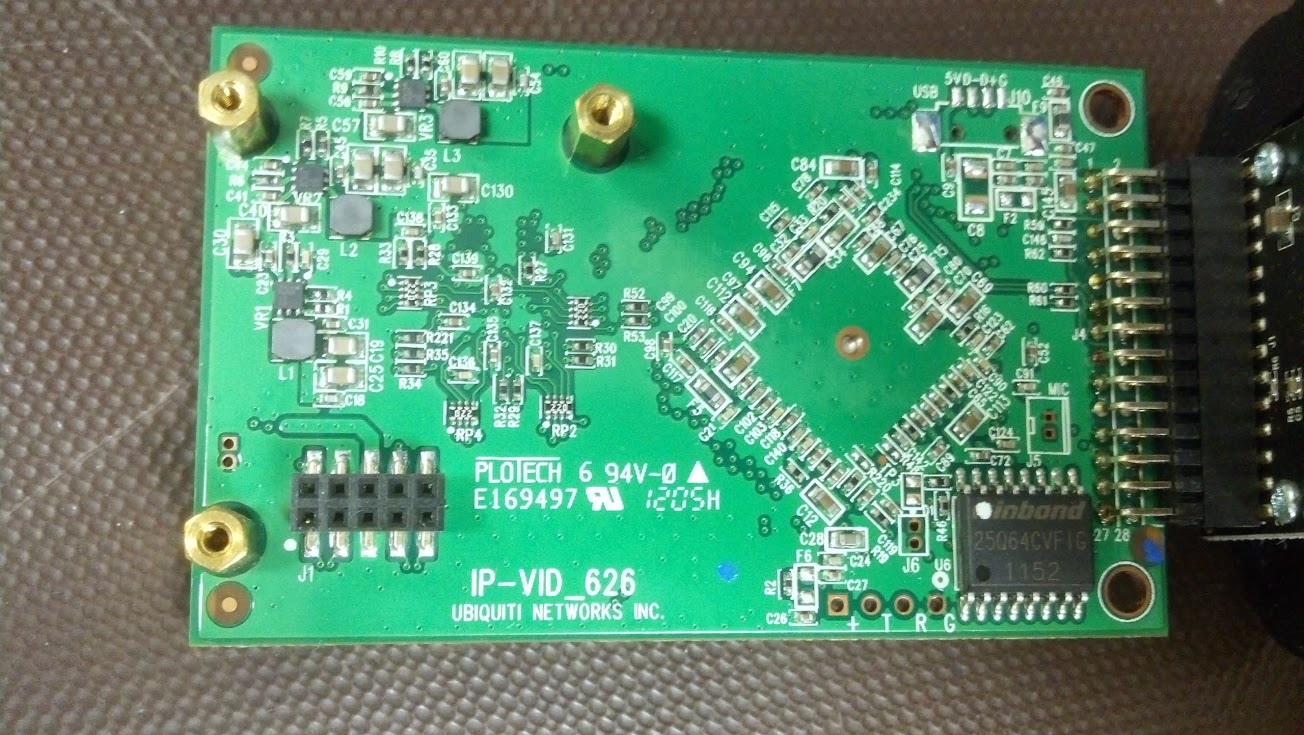

I opened up the camera (quite easy) buy removing the sun shield, unscrewing the lens cover, popping off the triangular face ring, and removing the black screws. Once removed, I could slide the camera/PCB board out of the body and engage in repair activities. The PCB/components are coated with what I suspect is an anti-moisture protector so make sure you have adequate airflow when doing any heating of the PCB.

I reflowed the small BGA package (U3) and touched the rest of the board with the hot air JUST in case there was a poor lead-free solder connection. Once reflowed, the camera snapped back to life (able to access the GUI, etc.)

As I’ve had issues with BGA components before (especially when using lead-free solder) I am not terribly surprised to see problems here. I’m happy to see that static electricity didn’t kill this device (apparently that is another common failure). My last camera would transit packets but not receive them (similar issue?)

Interesting side note that the device PCB has a USB connector site that can be populated. Not sure what for, but it’s there.

Hopefully these notes treat someone well. If you don’t have access to the right tools, I can help re-flow your failed AirCAM (if out of warranty) as a last resort. Contact me for details.